The class takes place a Tillers International, a curious yet very very cool organization, which (among other things) teaches classes on traditional crafts and skills. I will let their website do the talking for them on the count of what they do: http://www.tillersinternational.org/index.html

A few years ago I took their beginning blacksmithing class, which was quite good.

I took a LOT of pictures, so I will try to split things by days, and explain as I go along. I apologize in advance for the poor quality; the only thing I have to take pictures with is my phone. I am documenting this for my sake as much as for anyone else's; I want to get my notes down while they're fresh in my head, so I remember them later.

Monday

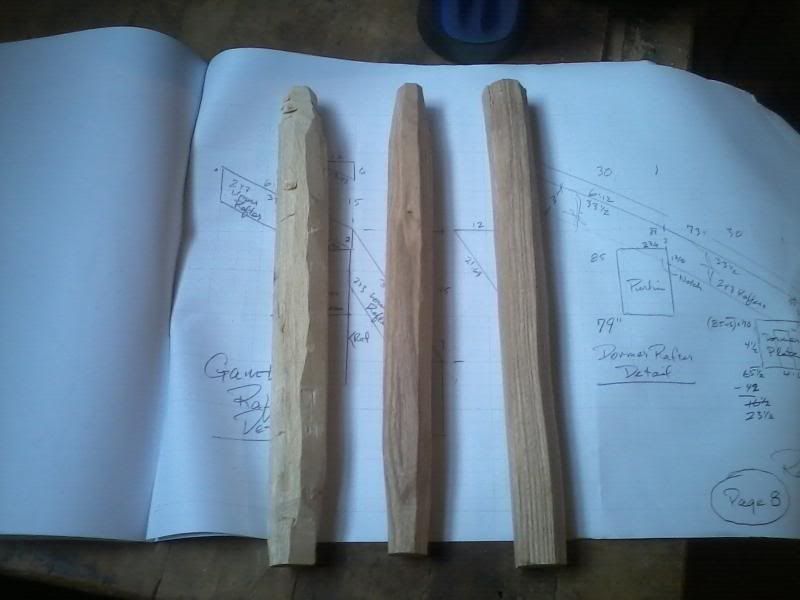

The morning of the first day, we learned how to carve a "slot" (called a mortise) and a "tab" (called a tenon). In the afternoon we toured several of the buildings on the grounds, to look at different design elements and unique joinery in the different buildings.

First, we toured the Blacksmith shop.

What I'm looking at in particular here are the little "shelves" carved into the joints, which give a great deal of additional strength to the structure.

There was a similar design in the woodshop, except that instead of being at an angle, there was a full housing for the end of the beam.

I don't recall exactly what I was noting here. The posts don't go all the way to the ground. They set on a raised cement foundation. This is especially important around animals, whose, eh, products can cause rot in the wood.

Noting a particular joint, with what I think is a shim.

This is a case of taking wood away to make it stronger. If the floor joist was cut with a 90 degree angle, the weight could cause the wood to split. With a more gradual curve, that is far less likely to happen.

The base of a post.

A nifty piece of joinery in the upstairs of the Granary.

I forget what this is called, but it's a unique frame design.

A joint for when the timber isn't long enough.

One of the first mortises I chiseled out. This is one with the slanted pocket, because it's for a brace.

A shot of the area. I really like how this pic looks.

This is what we used to start the mortises, drilling by hand. It's actually not too hard, because when you build a frame it's done with green wood. Add to that the fact that we're using tulip poplar for most of the frame, and it's pretty good!

Here's a shot of the blacksmith shop. It has six coal forges, each with an anvil on either side; so they can accommodate 12 students at once.

Here's a gate that was made on site.

Looking down towards our construction site. There are free range sheep, goats, chickens, and turkeys on the farm.